AAT3D Documents & Whitepapers

AAT3D Documents & Whitepapers Listing

Industry 4.0

How can AAT3D help in Industry 4.0?

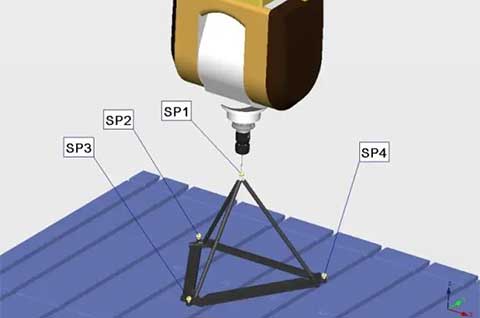

A high-end metrology software like CappsNC can perform all CMM tasks on a CNC machine.

CappsNC uses a separate PC that is connected to the CNC machine tool via Ethernet. This dedicated PC performs all the measurement calculations.

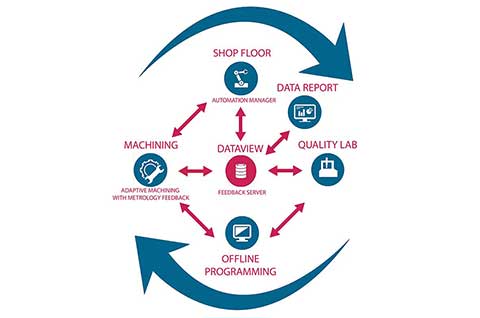

Industry 4.0 Smart Factory - Adaptive Manufacturing with Metrology Feedback

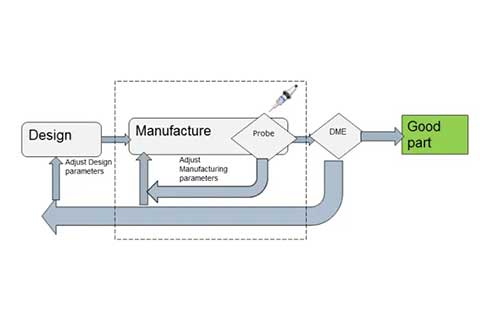

There are many technologies and equipment that have improved the manufacturing industry. CNC measurement using on-machine probing software is in this category.

CappsNC is measurement software that will work on CNC machines. The CNC machine can produce the measurement data through on-machine probing.

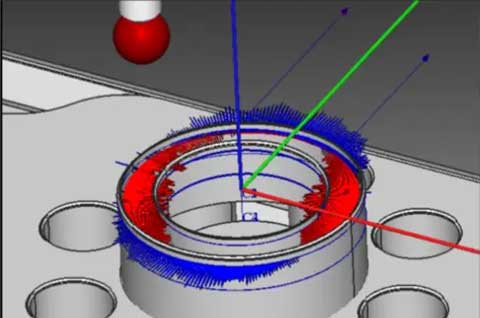

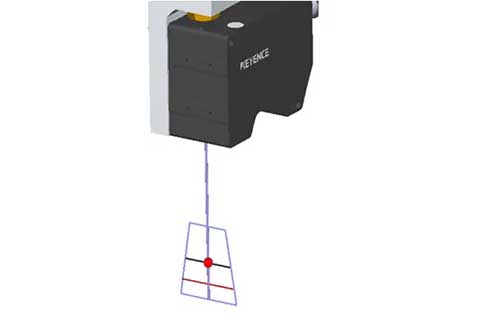

Blue Light Laser Sensor Integration and Point Cloud Metrology within the Manufacturing System

Measurement has been a part of a manufacturing system for many years. Measurement and manufacturing systems are being brought ever closer to meet the current production needs. Things such as a blue light laser sensor speed up the inspection process. This help us move closer to meeting production needs.