DataView Feedback

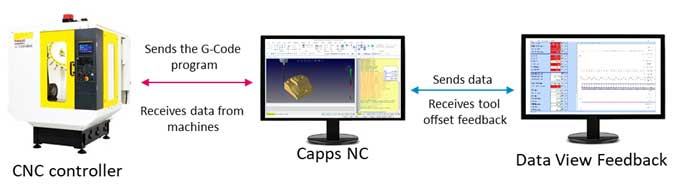

AAT3D DataView Feedback is a data display and feedback software. AAT3D developed it to monitor trends of feature measurements on different CMMs and NC machines. DataView can monitor from one central location and send feedback to NC machines to correct for any deviations in the tool offset.

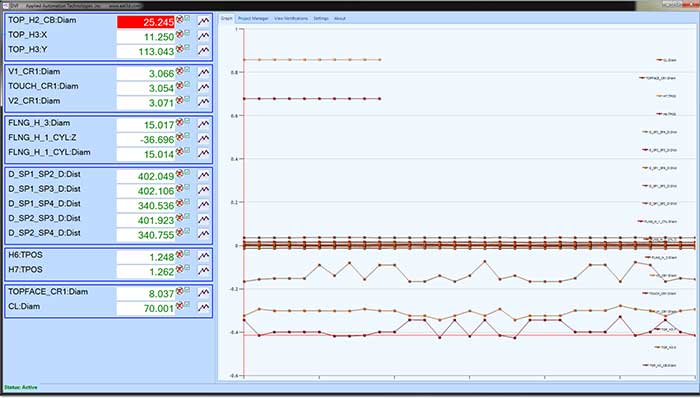

A simple yet configurable tabbed interface shows all the data as it is real time.

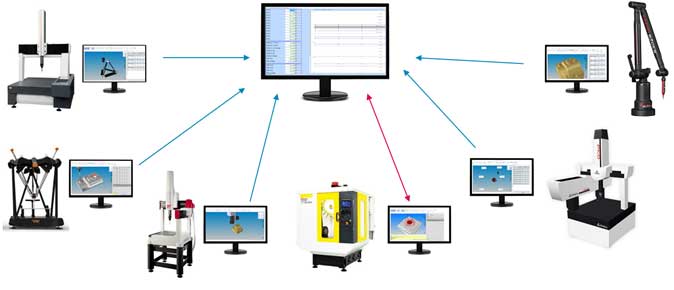

DataView Feedback can read data real time from several CMM or NC on machine probing cycles from within the factory, or even from the cloud.

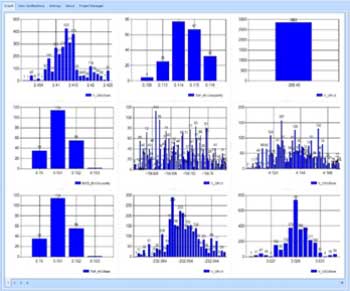

Each time after a machine executes a program, Data View Feedback will generate or append a graph to keep you informed.

Data view will display the actual value of the reported feature from the last run. Data view will separate features from connected machines will in boxes, avoiding confusion.

Data View Feedback uses string variables and mathematical formulas to calculate the deviation in tool offset. The administrator can easily customize the variables and add specific formulas to Data View. DataView sends tool offset correction feedback to the NC controller using AATRMI (AAT3D Remote Management Interface).

AAT3D is providing tools to enable Smart Manufacturing throughout you factory, for true Factory 4.0.