Software Products

AAT3D Software Products.

What is Capps?

Capps stands for “Computer Aided Part Programming System”.

There are 2 basic versions of Capps software :

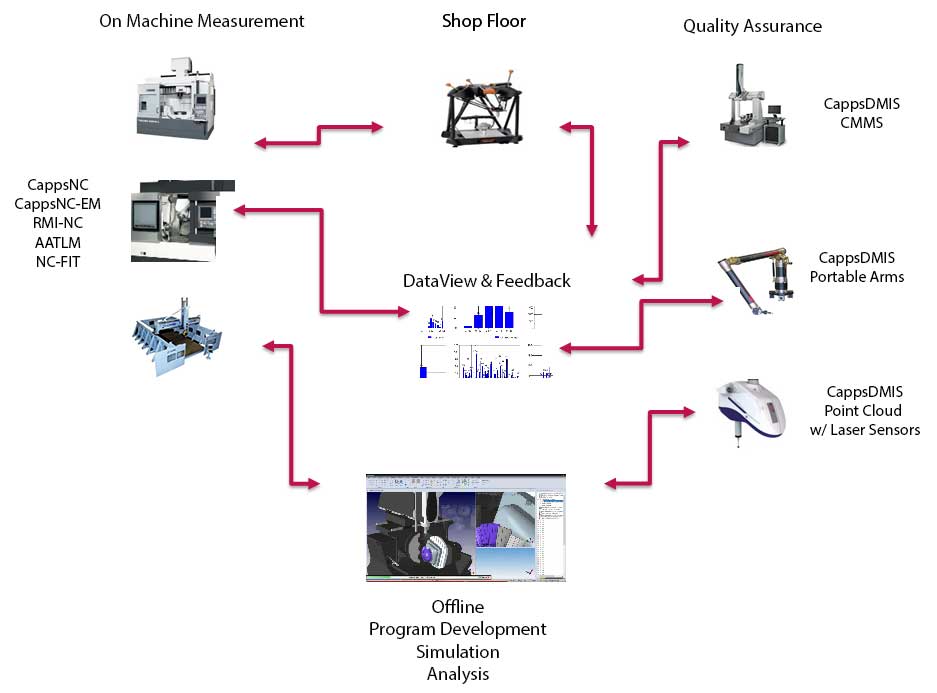

CappsNC on-machine probing software lets you create measurement data directly on the CNC machine tool. That resulting data can then be shared with all manufacturing devices, ensuring manufacturing facilities are running as efficiently as possible. The end result is Smart Manufacturing.

CappsDMIS is a universal metrology software solution for co-ordinate measuring machines. It is compatible with a large number of controllers. As a result, it is an ideal retrofit solution to breathe new life into your CMM.

Both CappsDMIS and CappsNC share these features:

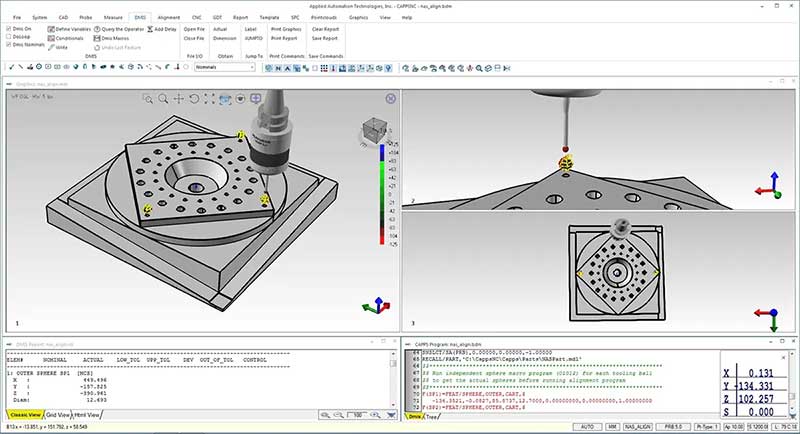

In the upcoming Capps 8.0 release, an entirely new clean & efficient interface has been created. As a result, use and navigation much quicker & easier.

As many people are familiar with ribbon interfaces in Microsoft Office, this familiar ribbon interface make using CappsNC & CappsDMIS that much more intuitive.

The ribbon interface helps you keep focused by organizing related functions into tabs on the ribbon bar. This organization results in a huge reduction of the need to go to multiple locations in the software to accomplish a single task.

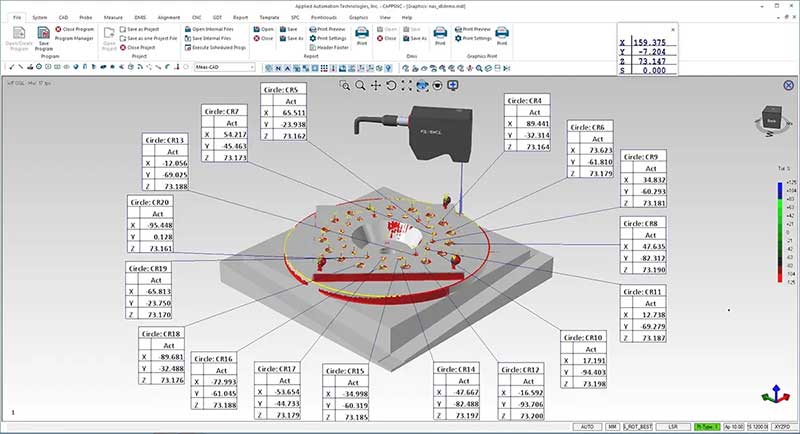

New & improved CAD engine with better graphics, multiple simultaneous views and advanced options make working with CAD quicker and easier. This results in faster programming tasks in CappsNC & CappsDMIS which in turn saves time and money.

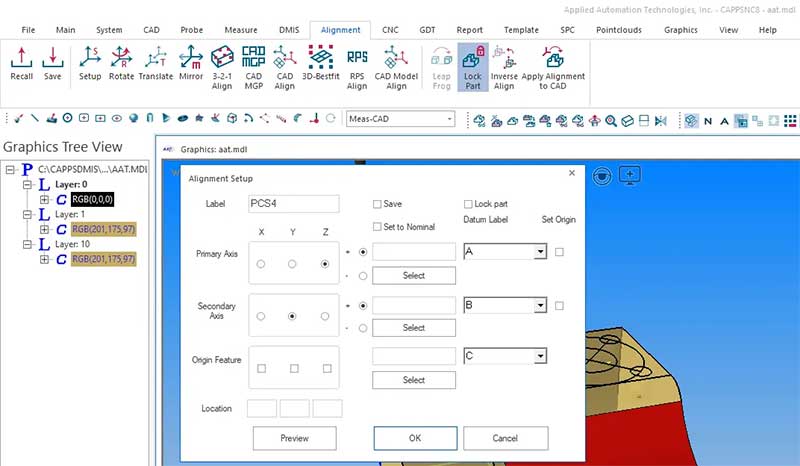

Extensive alignment options are a click away.

Everything from simple alignment setups and 3-2-1 alignments to more complex 3D Best-Fit alignments are all available in an intuitive, easy to use interface. These advanced alignment tools are also available in CappsNC, allowing your CNC machine to perform double duty as both a cutting tool and advanced CMM. This provides immediate feedback, resulting in more time available for cutting and less machine idle time waiting for results from the CMM lab.

Both traditional textural reports and graphical reports can be quickly and easily generated. You can cut a part and inspect a part on the same NC machine and provide reports ready to send to the customer.