AAT3D

How can AAT3D help in Industry 4.0?

A high-end metrology software like CappsNC can perform all CMM tasks on a CNC machine. CappsNC uses a separate PC that is connected to the CNC machine tool via Ethernet. This dedicated PC performs all the measurement calculations. CappsNC creates on-machine measurement programs offline in familiar DMIS language with collision avoidance and program simulations.

As soon as CappsNC measures features, CappsNC calculates results compliant to ISO and ANSI standards. That data is then used as direct feedback to the manufacturing process.

AAT3D’s Industry 4.0 philosophy is not to determine if the part is bad, as this is reactive instead of proactive. Rather, our goal is to be proactive, improving the process by capturing data directly from the CNC source.

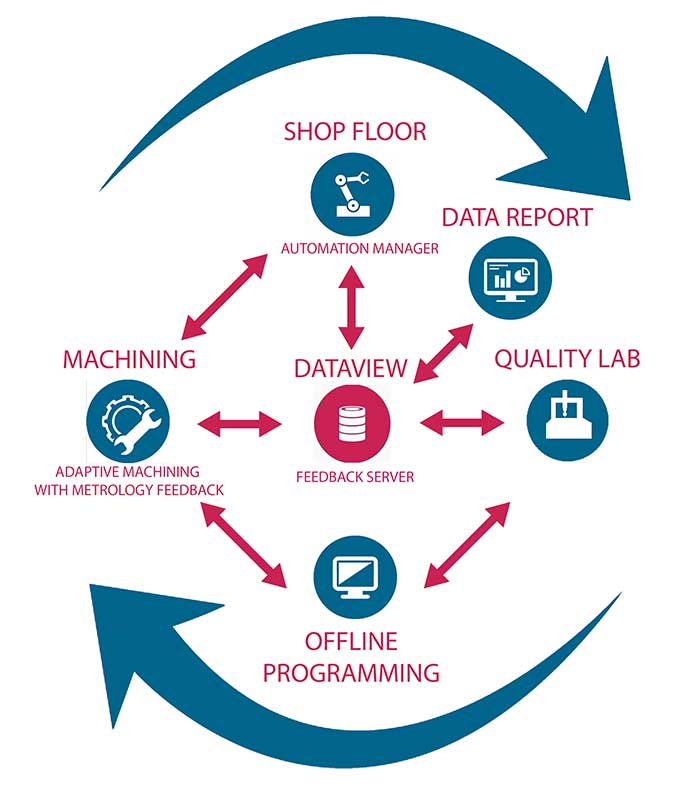

CappsNC converts measurement data from on-machine probing into manufacturing parameters in real-time. CappsNC feeds this data back to the CNC controller by using closed-loop feedback to adapt the machining process. In addition, CappsNC can store the resulting data in a database. The ability to produce measurement data on a CNC machine with a CMM level software is a must for adaptive manufacturing and Industry 4.0.

CappsNC gathers measurement data from the part being machined converts it into machining parameters. CappsNC can feed this data back to the CNC controller. As a result, the machining process can adapt to changing machining and environmental conditions. This closed-loop metrology feedback results in ’Smart Machining’. Smart machining automatically corrects and controls the machining process using “cut-measure-cut” to make good parts while minimizing costs and efforts.

Measurement data is an indicator of every factor that effects manufacturing. Our concept measures and stores all metrology data gathered from CNC on-machine probing.

CappsNC predicts changes in the CNC machining process and takes precautions against them. This is far superior to reacting after the process has gone out of control.