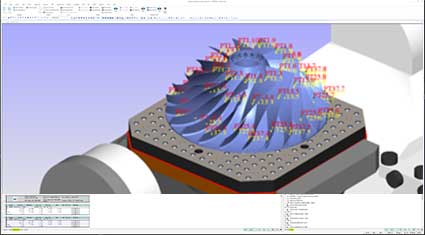

Impeller, Blade & Blisk Applications

Impeller, blade & blisk applications have their own unique challenges. AAT3D created Capps software to take on those challenges.

CappsNC supports 5-axis head configurations, both analog and laser scanning and multiple table configurations.

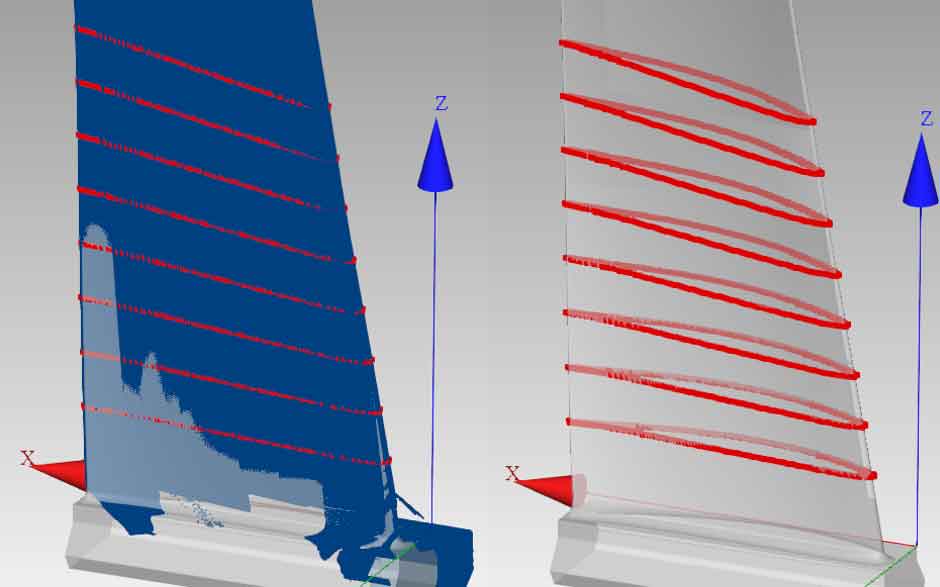

Using a blue light laser scanner, or a scanning probe such as the Renishaw™ Sprint, CappsNC can automate the machining process to need minimum operator intervention.

To automate the process, the blade is 1st scanned to get data on the part shape and location.

CappsNC adjusts the program to correct for any deviations and then posts the adjustments to the machine.

CappsNC can scan finished blades to generate complete inspection reports.

Additive manufacturing is becoming more popular for producing complex parts or repairing existing parts.

Hybrid machining centers include additive and subtractive machining in one system.

Repairing parts requires the repair material to be refinished. The refinishing needs exact alignment with the blade to be repaired.

CappsNC scans the blade with laser or analog scanning to get the part location. Once CappsNC has got the part location, it posts new offsets back to the machine to provide accurate machining from the known location of the blade. AAT3D CappsNC can measure critical surface points or blade sections before cutting to compensate for deviations.

Getting offsets for each blade using manually would be a long process. CappsNC automates that process.

Once the blade repair personnel have repaired the blade, CappsNC can generate a detailed “cmm-like” report complete with graphical reports.

Blisks require complex alignments. They also require complex part positioning to measure the part before machining.

CappsNC can combine head and table rotations to provide needed access to measure the part. Once CappsNC has measured the part, the measured data can be best fit to the CAD model to generate the alignment. CappsNC then posts any additional offsets to the machine.