CappsNC Machine Geometry

The measurement and monitoring of CNC machine tool geometry is critical to producing accurate parts. The critical geometry includes not just the machine, but also the head and the table.

The CNC machine tool head and machine tool table must be monitored on a regular basis to ensure machine accuracy when making parts.

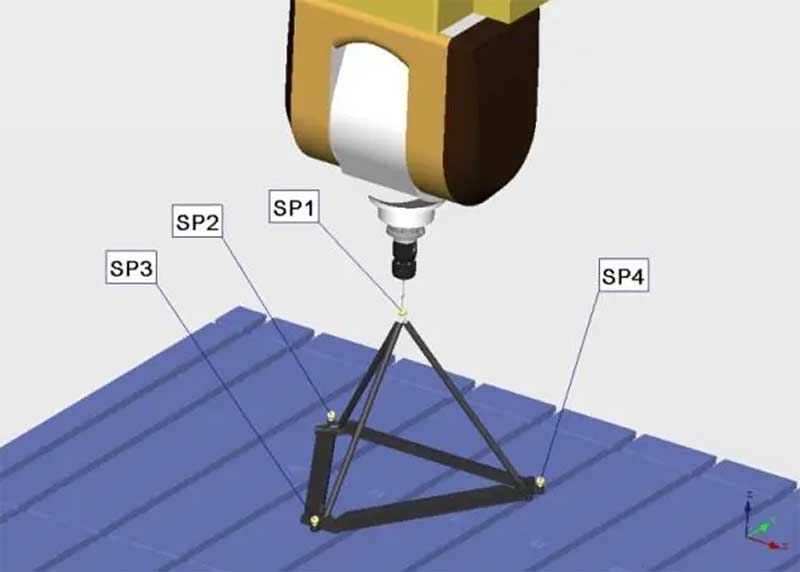

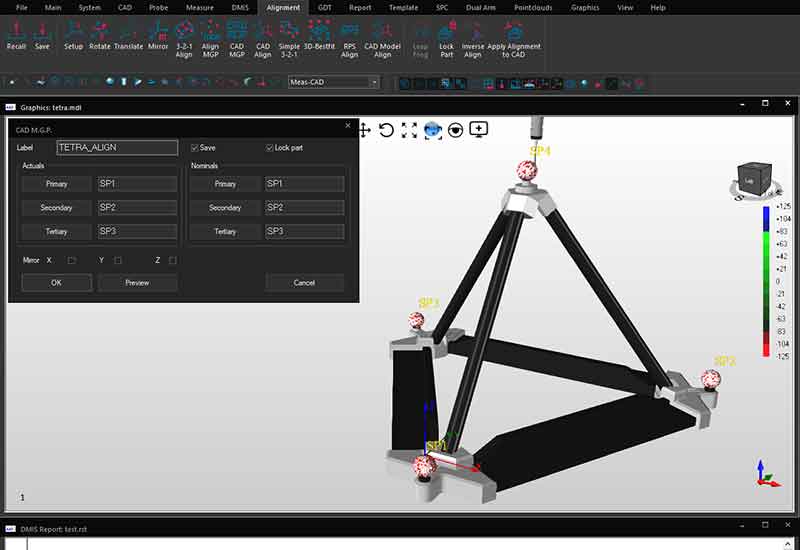

Simple test programs incorporating the Tetra-Gage Ball Bar System can easily be written in CappsNC on-machine probing software to help you better monitor your machine geometry.

The Tetra-Gage Ball bar system is a quick and easy way to verify your CNC machine geometry.

The Tetra-Gage replicates some of the B-89 ball bar positions without the fuss and difficulty of securely locating a ball bar in the correct position. When combined with the capabilities of CappsNC on-machine probing software, you have a quick and highly effective method of monitoring important machine geometry.