CappsNC - The benefits of on-machine probing

The Benefits & Features of CNC On-machine Probing. More and more people in the manufacturing sector are turning to on-machine probing software like CappsNC.

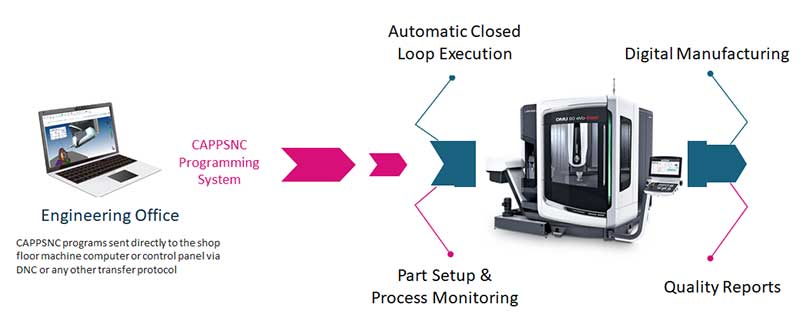

CappsNC can verify dimensions and alignment of the workpiece while still on the CNC machine with in-process, on-machine metrology.

Workpiece alignment is critical. Slight differences in the workpiece alignment can throw the tool-path off.

Touch probes are excellent when confirming the size and location of a fixture or workpiece.

On-machine probing with touch probes, scanning probes or non-contact sensors can measure quicker and with fewer errors that manual measurement. On-machine probing saves time, improves accuracy, and reduces errors.

Making sure tooling is in the correct position with the correct offsets is as critical as accurate positioning of the workpiece. Slight errors in the tool offset can throw a machining pass off. This can cause a workpiece to be scrapped and possibly expose the machine tool to damage. In-process, on-machine probing can detect tool setting errors or tool wear. As a result, we can avoid potentially expensive errors.

CNC on-machine probing can improve efficiency. Multiple steps and time are saved by not removing the part from the CNC machine and taking it for inspection. In many cases, when a part is removed from the CNC machine, it cannot be placed back in the exact location. As a result, if the part is found to be incorrect, saving the part may not be possible, resulting in scrap. With CappsNC on-machine probing, “measure-cut-measure” can be performed on-machine and can use direct metrology feedback. This can cause reduced rework/scrap, saving time and money.

CappsNC on-machine probing software can also improve process control. CappsNC can find errors by measuring the workpiece while still in the manufacturing process. When working with a hard material, for instance, tool deflection can cause less material removal than expected. On-machine probing can detect when the part is outside tolerance throughout the process. When CappsNC detects a tolerance problem, it notifies the user or the machine can automatically adjust.